Sir Archibald Russell started to work at Filton for the Bristol Aeroplane Company as

an assistant stress calculator in 1925 in the era of biplanes and retired as

Chairman, Filton Division, British Aircraft Corporation in 1969 in the era of the

supersonic airliner.

Russell was raised in the Forest of Dean and attended the school where his father was

headmaster. When he was fifteen the family moved to Bristol and his education

continued at Fairfield Grammar School, and then the Engineering faculty of Bristol

University where he gained a BSc in automotive engineering. His first job was

maintaining buses for the Bristol Tramways and Carriage Company (one of Sir George

White's companies).

Another of Sir George White's companies was The Bristol Aeroplane Company founded in

1910. Bristol made their name with the

Bristol Fighter biplane making over

5,500 during the Great War. They were making the last of another 600 when Russell

joined the company. He met Miss Lorna Mansfield, a secretary at the company, and they

were happily married for over 50 years.

Biplanes to Monoplanes

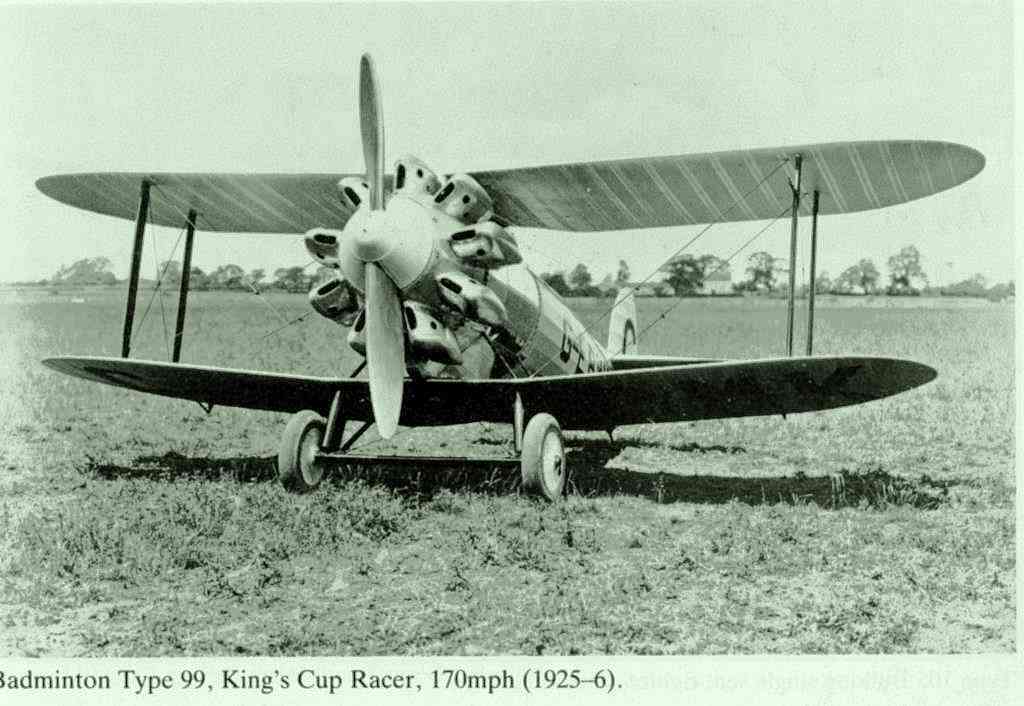

The years following the Great War were lean times for warplane manufacturers. Of 56

distinct Bristol designs only 18 reached flying prototypes and only 2 entered

production. One unsuccessful plane was the

Badminton, for which Russell did

the wing stress calculations, and specially designed for the 1926 King's Cup air

race, He was gravely concerned when the plane crashed a month before the race killing

the pilot. It turned out that the uprated engine had seized solid.

The

Bagshot of 1925 was an attempt at a monoplane fighter but it did not

perform well. Russell was sent up with the test pilot and he observed quite alarming

twisting of the wings.

(The two wings of biplanes could be strutted and stayed to form a rigid 'box'

with high torsional stiffness) After inconclusive consultations with various

academics Russell realised that the bending and torsional stresses could be

calculated independently. He was later granted a patent on a single spar wing design

using these principles.

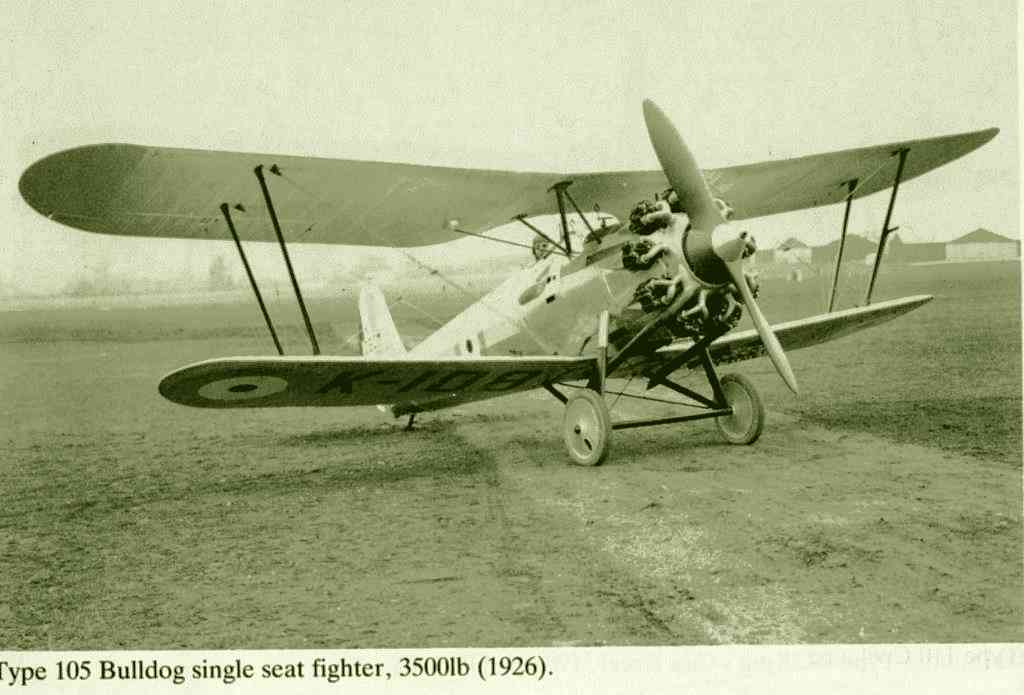

There was to be another successful biplane fighter from Bristol in the

Bulldog (1928).

Russell did the stress calculations for the wings and was an interested

observer of the loading tests that proved the validity of the calculations. A near

complete plane was suspended upside down and the wings were progressively loaded with

1600 bags of lead shot each weighing 16 lbs. In total 440

Bulldogs were

built including exports to many countries including Japan.

In the early 1930s a new sheet material became available. This was Alclad, a sandwich

of thin layers of aluminium (for corrosion resistance) over a layer of duralumin (for

strength). Covering a wing frame with this material gave a smooth surface and also

increased the torsional stiffness.

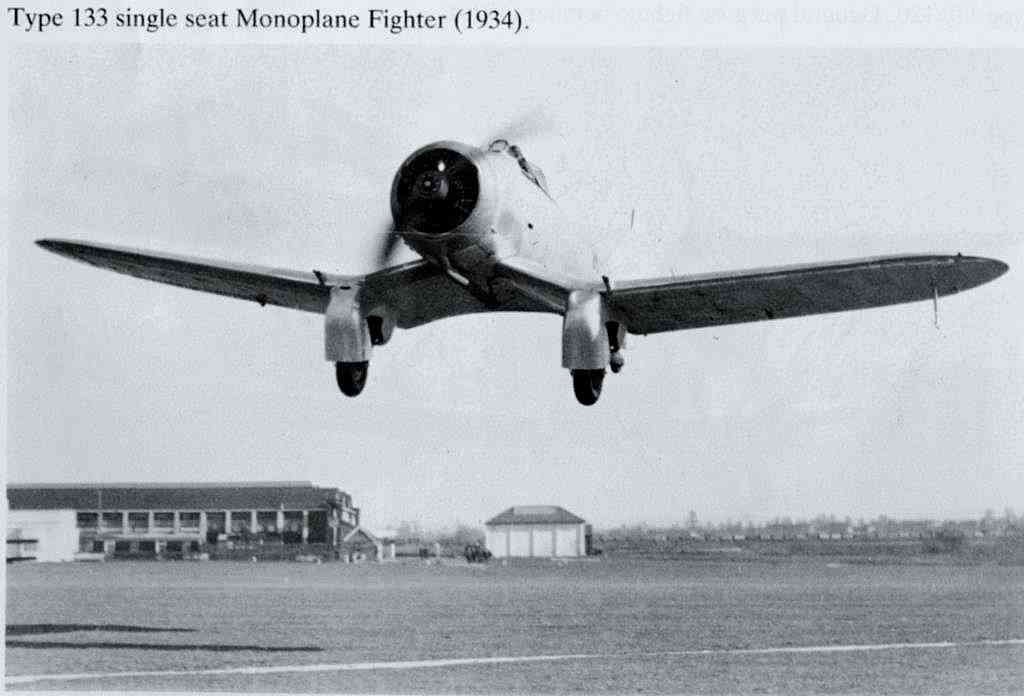

Now the company built the handsome Type 133 monoplane fighter of 1934. This plane

could fly at 250 mph and was 25 mph faster than any serving fighter or prototype

around. With all tests satisfactorily completed the plane looked like a winner, but

the day before official trials it was destroyed in a bizarre accident due to pilot

error. Contracts were placed for its slow rival the Gloster

Gladiator -

another biplane. The future looked bleak for Bristol.

Planes for World War II

Lord

Rothermere ordered an aeroplane with the highest possible speed, a crew of two, and

cabin space for six passengers. Earlier plans for a small airliner were dusted off,

and soon Lord Rothermere had a twin engine monoplane Type 142 (1934) that could fly

at more than 300 mph. He named it

Britain First and used his newspapers to

boast that his new plane could fly 50 mph faster than the very latest RAF

fighters.

With a minimum of effort and a great deal of foresight the Type 142 was transformed

into a bomber the Type 142m

Blenheim (1936). The wings were raised from the

low position to mid fuselage to make room for a bomb cell with 1000 lb bomb capacity.

The Air Ministry placed orders for 718. Russell was made head of the Technical Office

responsible for stressing, structures development and tests, aerodynamics and weight

estimation. Derivatives from the

Blenheim using higher wing loadings,

increased engine power, higher payloads, gun turrets, radar etc. included,

- Bolingbroke (1937) - Coastal reconnaissance for the Royal Canadian Air

Force

- Beaufort (1938) - Tactical reconnaissance and torpedo carrier

- Beaufighter (1939) - Multi-role fighter/bomber

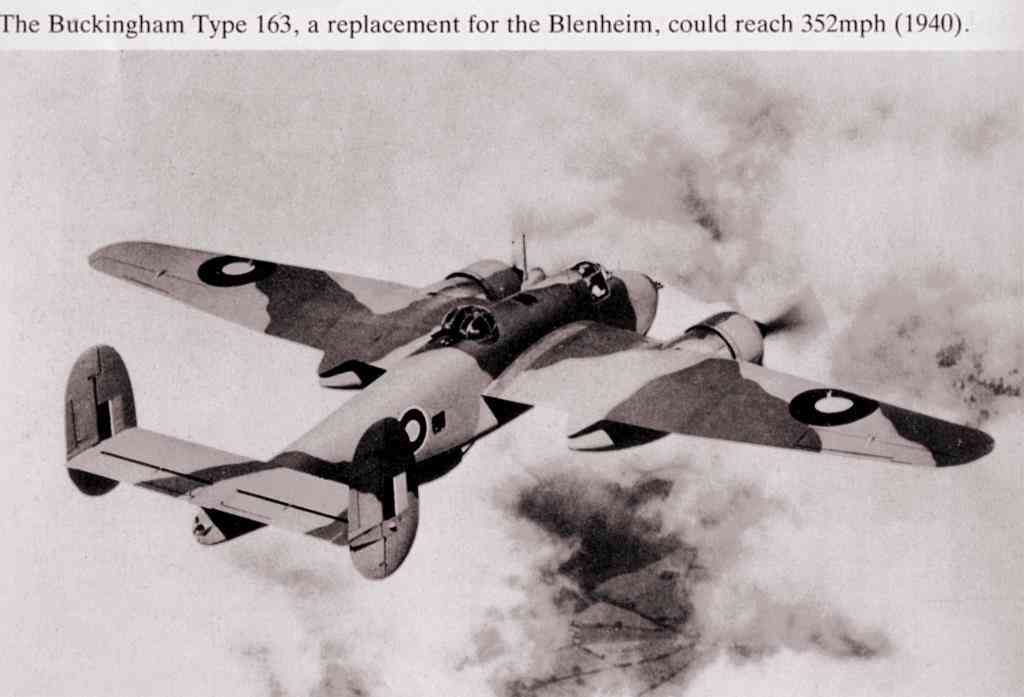

- Buckingham (1940) - Bomber

- Brigand (1944) - Torpedo carrier

Blenheims

Blenheims were made in Canada,

Beauforts in Australia, and

large numbers of

Beaufighters were rolled out at Bristol and various shadow

factories. The

Buckingham was the fastest fully armed day bomber (330mph) of

its time, but when the Americans entered the war they took over day bombing, and

Buckingham production tailed off. In the midst of hostilities Bristol was

left without any new design work.

The best that came the company's way was a Design Study Contract for a bomber capable

of carrying an 80,000 lb. bomb load to Berlin at as high a cruising speed as

possible. For ten years the company had been designing medium sized twin-engine

monoplanes. Russell learnt all he could about streamlining and aerodynamics, so that

drag could be minimised in the big bomber. To provide sufficient power eight 2,500 HP

Centaurus engines were required. Arranged in pairs driving contra-rotating propellers

they could all be housed within a wing, with a span of 230 feet and area of 5,000

square feet, again minimising surface drag. Russell became Chief Designer and soon

the opportunity came to redesign the bomber as an airliner.

Post War Planes

The Brabazon

The Government had set up a committee under the chairmanship of Lord Brabazon to

determine post war policy for civil airliners.

In February 1944 a

contract was placed with Bristol for detailed design of a luxury airliner for British

Overseas Airways Corporation (BOAC). Russell was appointed Chief Engineer and assumed

full responsibility for the

Brabazon. Original development work was required

on vibration testing, ac electrics, hydraulically powered flying controls etc. The

prototype, with Centaurus engines, flew in 1949

Unfortunately another new technology was overtaking the project - jet engines. De

Havilands were developing the

Comet with pure turbine engines, and Vickers

were developing the

Viscount with turbo prop engines. BOAC wanted Bristol

Proteus turbo prop engines in the next prototype

Brabazon.. By 1950 it was

obvious that the Proteus was not sufficiently developed to do the job and the

Brabazon project faded into history.

There were other more successful ventures at this time. The Directors instructed

Russell to produce a modest 'aerial truck' and the result was the twin-engine high

wing

Bristol Freighter that first flew in December 1945. The plane and its

passenger version Wayfarer sold in reasonable numbers to small operators all over the

world. They are well remembered for their car ferry operations.

As Chief Engineer Russell was also responsible for a recently acquired helicopter

company, that manufactured single and twin rotor machines, and for another

engineering group within the company that manufactured guided missiles, with ram jet

engines. The Bristol Ferranti Bloodhound was used by the Royal Navy, the RAF and was

also adopted in Sweden and Australia.

The Britannia

In 1947 Bristol won a design competition for 'An airliner to required to carry thirty

six passengers on routes to South Africa, Australia and the Far East.' The number of

passengers (36) had been set by the capacity of the standard BOAC airport bus!

Russell redesigned the plane for sixty eight passengers. Two years on BOAC wanted

Proteus turbo prop engines in this plane as well. The wing area and span of the

Britannia was increased, for greater altitude and speed and seating was

raised to 96 without altering the fuselage.

The

first prototype flew in August 1952 using the substandard Proteus engines. Little

more was achieved until December 1953 when the second prototype flew with the much

improved Proteus III engines designed by Stanley Hooker. Unfortunately an engine

exploded on a demonstration flight in February 1954 and with fire risk in mind, the

pilot ditched the plane in the mud of the Severn. The fault was failure of the

reduction gearing of the engine, and the solution was to change from straight to

helical toothed gears.

Worse was to follow for the

Britannia project, and for the British aircraft

industry in general. The De Haviland

Comet was the first jet engine airliner

in the world but it was grounded after three crashes in quick succession, the last in

April 1954, all due to metal fatigue. A water tank fatigue test became mandatory for

all British airliners and the

Britannia was probably the most thoroughly

tested plane ever at the time. There was further delay when icing problems in the

engines nacelles were encountered in of all places the Tropics! A solution to BOAC's

satisfaction took another year.

Britannia finally entered service in 1957 - 3 years late. It was a fine

aeroplane, but bigger pure jet airliners were now just around the corner and the

plane became a stopgap for major airlines. Ninety Britannias were built in Bristol

including twenty for RAF Transport Command and some exports. A long range version of

the plane could carry 96 passengers, non stop from London to New York, fulfilling the

dream of the original

Brabazon. Another 87 variants of the plane were built

under licence in Canada for military and civil use.

Last years of Bristol Aeroplane Company

The

Brabazon and

Britannia stories illustrate a weakness of the

civil aviation industry in the United Kingdom in the post war years. Russell pointed

out that the National carriers BOAC and BEA 'had unwisely been granted the privilege

of bespoke tailoring their aircraft requirements, heedless of international sales

potential.' None of the manufacturers were reaping the benefits of long production

runs.

After

the very successful Vickers

Viscount, BEA ordered a new turboprop plane the

Vanguard at very high cost, instead of a modest modification of

Britannia. Bristol had a three engine design (Type 200), the very first of

this configuration, but BEA bought De Haviland

Tridents, whilst the rest of

the world bought

Boeing 727. The

Boeing 707 was sold world wide,

but BOAC bought the

Vickers VC10. Bristol was losing out all round and

reorganisation of the industry was inevitable.

Russell took the opportunity in these lean times to learn about supersonic flight.

Bristol built two stainless steel research planes (Type188) designed for Mach 3, but

limited in trials to Mach 1.8 by underpowered engines. From the Royal Aircraft

Establishment at Farnborough, Russell also learned of a 'breathtaking novelty' for

supersonic flight - a narrow delta wing with a sharp leading edge. With immediate

separation at the nose, the airflow rolls up into a strong vortex over the wing.

Contrary to all existing streamline theory there was no aerodynamic penalty with this

vortex. The configuration also reduced stall to such an extent that landing flaps

were un-necessary.

American manufacturers were considering Mach 3 planes but Bristol settled on Mach

2.2. This was the maximum speed for which the surface temperature rise would not be

excessive using the latest aluminium alloys. The Bristol design study of 1959 and the

revision (Type 223) of 1960 for a transatlantic airliner had a narrow delta wing, a

variable geometry cockpit and engines in nacelles under the wings.

Concorde

as built looks remarkably like these studies. But reorganisation came first.

In 1958 there were still 27 aircraft companies and 7 engine manufacturers in the

United Kingdom. The Minister of Aviation forced the industry to organise itself into

two aircraft groups. In 1960 Bristol aircraft merged with Vickers Armstrong, English

Electric and Hunting as the British Aircraft Corporation. Russell was appointed

Managing Director, Filton. The other group was Hawker Siddeley.

Concorde

The strongest player in French aviation was Sud Aviation based in Toulouse after

their successful

Caravelle jet airliners. Sud had been doing design studies

for a smaller Mach 2 transcontinental airliner, assuming that America would produce a

Mach 3 intercontinental airliner.

There was considerable politicking, not least Prime Minister Heath's desire to take

the United Kingdom into the Common Market against French opposition. In 1962 the two

Governments signed an agreement that British Aircraft Corporation, Sud Avation,

Bristol Siddeley Engines and SNECMA the French engine company, should cooperate to

design a single supersonic aircraft in two versions one long range and one short

range. Bristol Siddeley already had a proven engine in the Olympus, and took the lead

in engines. To balance this Sud Aviation took the lead in the aircraft. M. Pierre

Satre, the acclaimed designer of the

Caravelle, was appointed Technical

Director and Russell was appointed Deputy.

Somehow

the project survived political problems, national pride and jealousies, cost rises,

environmental objections, duplicate production lines and technical problems. It was

the French that proposed dropping the short range version. The first metal was cut in

1965, and the first prototype flew in March 1969.

Concorde was a technical

triumph but was not a commercial success. The only buyers were British Airways and

Air France.

Russell was appointed Chairman, Filton Division of British Aircraft Corporation in

1968 and retired in 1969.

Postscript

Airbus Industrie was a product of commercial interests between Hawker Siddeley and

German and French companies. Without government support Hawker took only a 20 % share

of Airbus. In 1977 the government nationalised the aircraft industry merging British

Aircraft Corporation and Hawker Siddeley, and the new British Aerospace inherited

Hawker's stake in Airbus.

The very core of Sir Archibald Russell's many talents was designing wings and

calculating stresses. Perhaps his greatest legacy is that the wings for all of the

Airbuses have been designed at Filton in Bristol, and Airbus Industrie is now the

largest manufacturer of airliners in the world.

John Coneybeare August 2005